Through 15 years of growth and development, the QK Group has taken its lead from our customers – customers that most definitely know what they want.

What we were determined to do was not bombard with new invention, but complement and support, with ever better service and practical solutions.

The service that built the reputation of our World renowned brackets and mounting kits soon led to requests for bespoke versions – we naturally grew our offering both by request and by design and development; products and services that went beyond what customers requested, to give them choice, increasing functionality and quality.

The new products, together with tried and tested off the shelf components, are constantly improved upon, simply by listening to customers.

One of these developments resulted in our own design for a robust and efficient Stainless Steel Spring Return Handle – we weren’t reinventing the wheel – but giving it a massive upgrade.

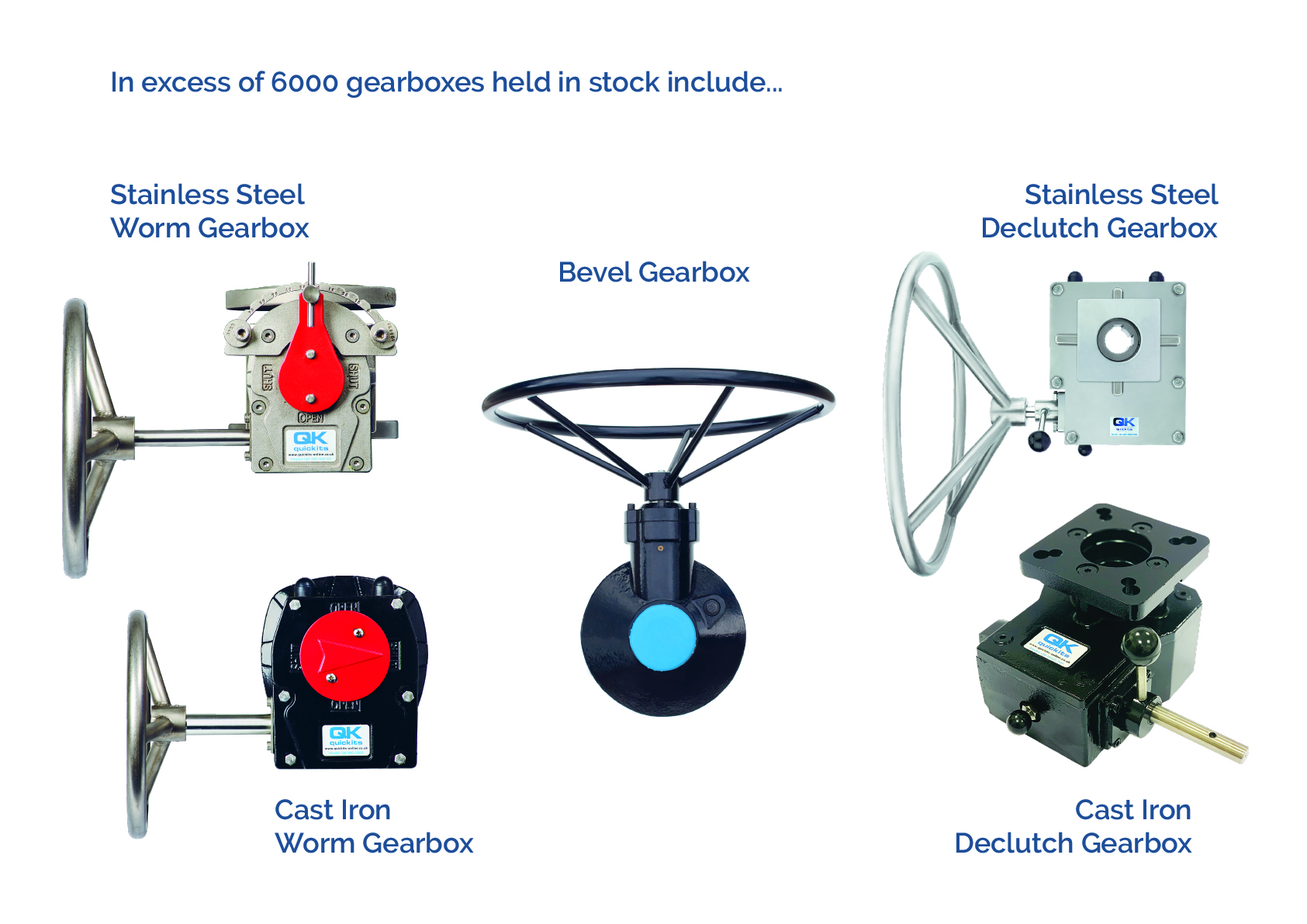

The very best available Gearboxes are another typical example of popular off the shelf products, which we have specified, sourced and stocked ready for same day delivery.

In stock now are Quarter turn Cast Iron Worm Gearboxes, ideally suited for HVAC, Chemical, Power and Waterworks, amongst general industrial applications – alongside Stainless Steel Worm Gears designed to operate in the harshest environments.

Between them, both Cast Iron and Stainless Steel versions of the QK WG De-Clutch Gearboxes cover all Manual Override needs, while Multi-turn operations are reliably catered for by QK’s Cast Iron Bevel Gearboxes -covering a wide range of specifications and options.

Demand for stock products, ready for immediate dispatch, has meant an additional investment in 2019; to gain another 4000 square feet of warehousing and testing / dispatch facilities – dispatch that was already in the highest percentile of the industry’s on time deliveries.

We expect to be extending again as part of our planned growth through 2020/21

A comprehensive and constantly developing range of standard products sourced from around the world, together with reliable on time deliveries became an introduction to other services and products – making QK a one-stop shop for the Process Industry and resellers alike. Our Precision CNC manufacturing facilities being discovered by Stock Product customers while customers for our Manufacturing Services have become buyers of our Stock Products.

Both sides of Quickits Ltd work independently and in conjunction to provide whatever service suits the customer – with the added benefits of the QK Group offering of Laser Cutting, CNC Braking and now Powder Coating services.

The leadership at QK Group is never satisfied with the status quo; we are always looking at any way we can improve and progress.

In 2019 we retired a lot of machines that had produced great work over the years, simply to make way for new plant that would increase even further our manufacturing capacity and efficiency – a planned growth strategy already paying dividends for our customers.

New Machinery as upgrades to increase efficiency, capacity and even greater accuracy.

• XYZ 1100HD CNC Milling machine with 4th axis

• XYZ 1510 CNC Milling machine

• 2 x XYZ 555

Proturn CNC Lathes

• XYZ 65LTY with Bar F

eed

• XYZ Turning Centre 320LTY with Bar Feed (not shown)

Additional New Machines to add capacity

• XYZ 800HD CNC Milling machine with 4th axis

• Lincoln Aspect 300 Fully

Watercooled Aluminium TIG Welder

The upgrade has already shown a return on investment – not only financially but by allowing our Design and Project Management services even greater flexibility in supporting customer specifications.

We use Solidworks CAD/CAM software to highlight any issues relating to interference detection and clearance verification, while our in-house developed Solidworks software produces production drawings with optimum efficiency.

There is much more to find out about Quickits Limited and the QK Group, come along and find out.

Originally Published in Valve User Magazine Issue 52